MES offers PIPING SYSTEM INTEGRITY INSPECTION & ANALYSIS.

CORROSION ANALYSIS

The first step in understanding corrosion in your piping

system is to determine the root cause. MES

can assist you by providing chemical analysis of your corrosion debris and working fluids.

ONSITE INSPECTION

MES provides on-site engineers and technicians to perform

non-destructive inspection of your piping system. Inspection techniques may include ultrasonic

thickness checks, borescope inspection, pressure checks, or guided wave ultrasonic inspection.

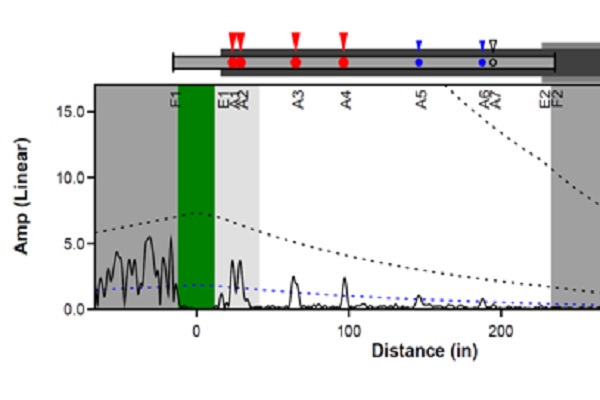

Additionally, MES offers Guided Wave Ultrasound Testing (GWT), one of latest methods in the field of NDT for evaluation of corrosion damage and other defects in elongated structures, such as pipelines and buried anchor rods. The method employs mechanical stress waves that propagate along an elongated structure while guided by its boundaries. This allows the waves to travel a long distance with little loss in energy.

REMEDIAL ACTIONS

Once we understand the problem, our team of metallurgists, chemists, and material scientist can help you make intelligent decisions on repair or replacement.

APPLICATIONS

Buried pipe

Insulated pipe up to 340°C

Boiler tubes

Road and rail crossings

CAPABILITIES

Inspection of 100% of pipe/rod volume

Rapid identification of corrosion damage in buried or covered structures

Ability to detect corrosion and other defects

Monitoring for corrosion over time

Collect corrosion data at difficult to access areas

Portable equipment

SPECIFICATIONS

ASTM E 2775

SAMPLE REQUIREMENTS

Sample Diameter Sizes – 1″ to 40+” diameter

Removal of about 1 meter of insulation

Surface preparation to scrape off loose paint or scale